What is a blast chiller?

A blast chiller is a professional kitchen appliance that is used to quickly lower the temperature of cooked food, whether hot or cold, to a safe storage temperature. They are used in both home and professional kitchens due to the range of benefits they provide to users.

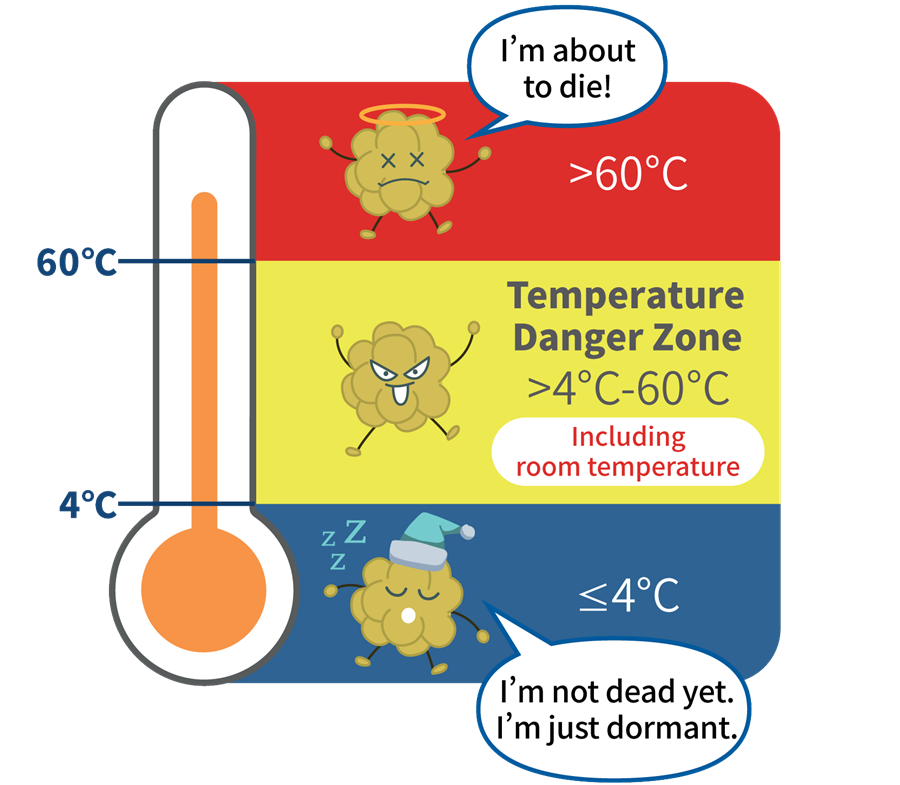

The blast chilling process involves rapidly reducing the temperature of food to below 4°C (40°F), which prevents the growth of bacteria and helps maintain the quality and safety of the food. This rapid cooling process prevents the formation of large ice crystals, which can damage the texture and taste of the food by disrupting cell membranes. In addition, blast freezing minimizes the time that food is in the “danger zone” temperature range (where bacteria can grow).

Blast chillers typically use powerful fans and refrigeration systems to rapidly circulate air around the food, speeding up the cooling process and helping to maintain and meet food safety and quality standards.

Why use a blast chiller?

Hygiene and safety

All fresh organic food products contain a natural bacterial load, which under favorable environmental conditions (temperature and humidity) multiplies, causing dangerous effects on the health of consumers.

Between +65°C and +3°C: in this temperature range, the multiplication of bacteria accelerates exponentially. Blast chilling means lowering the temperature of the product from +90°C to +3°C in less than 90 minutes. Passing through the critical temperature range in a short time leads to the inactivation of harmful bacteria. Blast chilling of a cooked product not only prevents bacterial proliferation, but also extends the shelf life of the product, avoiding the loss of taste and aroma. The quality of the food is not affected by increasing the shelf life of the product.

Workflow streamlining

Blast coolers allow a large amount of product to be prepared and after shock cooling it can be consumed for a period of 5-7 days, while with shock freezing, the duration of the frozen product can be extended to several months, maintaining the organoleptic state of the food.

Preserving product quality allows for advance planning of food preparation processes, optimization of product purchasing, as well as a number of advantages in terms of hygiene and menu diversity.

Save Time

Preparing food and blast chilling it allows restaurants to offer a tastier and more varied menu.

The chef does not have to constantly monitor the process of preparing several dishes. The simple operation of reheating food allows a wide range of dishes to be served in a short period of time. Blast chillers increase production capacity, thereby reducing personnel costs and providing outstanding advantages in terms of profitability and time.

Quality

The rapid temperature drop makes it possible to preserve the moisture content of foods and prevent normal bacterial proliferation. Shock freezing promotes the formation of intercellular microcrystals that maintain the compactness, taste, freshness and characteristics of foods over time.

Shock chillers are also exceptional in preserving fresh and raw foods, such as fish, shellfish, vegetables, bread and partially cooked products such as fresh pasta and sauces.

Applications

This kitchen work streamlining system is extremely useful for all niches of the gastro industry and especially for catering, canteens, hospitals and restaurants, as well as for special occasions such as large banquets. It also allows restaurants and catering businesses to offer their well-presented dishes that are ready to eat.

Other benefits

Blaster chillers optimize inventory management by:

- Reducing weight loss due to natural evaporation of moisture from cooked food

- Planned food purchases, thus improving kitchen organization

- Dramatically reducing waste and unused food

At Tirol Professional, we know that food safety and quality are a priority for every Chef. To optimize your business and make your menu presentation uncompromising, we offer a wide range of combined blast chillers and freezers in different sizes. The Fagor range includes blast chiller models specially designed for combined installation with convection ovens. The combined use of convection ovens and blast chillers (Cook&Chill) allows you to be even more efficient, helping you to program your work in the kitchen, resulting in less waste, saving time and optimal results.