Commercial Brema Ice Machines – Series, technologies and applications

When it comes to professional kitchen equipment, a reliable ice machine is a must-have for restaurants, bars, hotels and catering companies. At Tirol.bg, we are the official distributors of Brema—the Italian leader with over 40 years of experience in ice-making technology. In this guide, we’ll help you choose the right model, explore the various technologies and ice formats, and explain why you should trust us.

The company’s motto “Shaping the Ice” is clearly demonstrated by the variety of ice formats offered by Brema Ice Makers.

Types of Ice and Their Applications

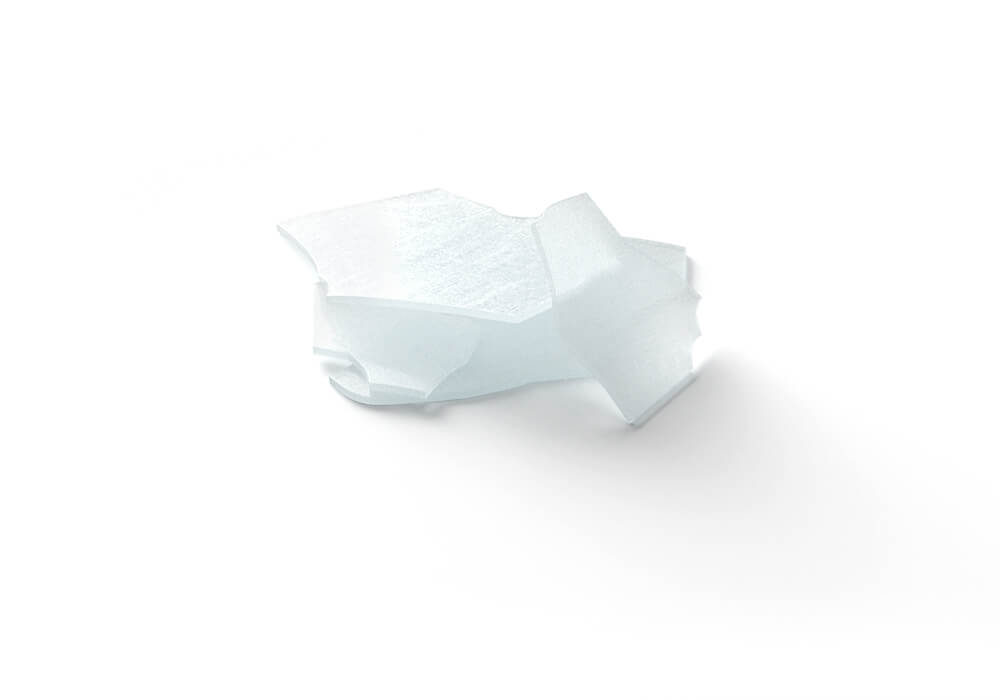

B-Qube

The Glam Cube • Shape: Solid transparent cube with precise edges • Technology: Spray system • Advantages: Exceptional clarity and strength; won’t crack during shaking; delivers controlled dilution in the shaker • Applications: Premium cocktails, high-end bars

Ice Cube

The Classic Cube • Shape: Solid transparent cube in various sizes (13–63 g) • Technology: Spray system • Advantages: Harmonious clink sound in the glass; enhances the flavor of drinks • Applications: Universal use in restaurants, cafés and hotels

Ice Finger

Hollow Cylinder • Shape: Elongated cube with a hollow center • Technology: Paddle (immersion) system • Advantages: Fast cooling thanks to large surface area; ideal for hard water conditions • Applications: Sports bars, juices, soft drinks and water stations

Fast Ice

Quick-Break Ice • Shape: Small cube (~7 g) • Technology: Vertical evaporator + PAM treatment • Advantages: Rapid production; perfect for carbonated beverages • Applications: Fast-food outlets, busy cafés and high-volume bars

Ice Pebbles

Granular Micro-Cube • Shape: Hybrid between a cube and a pellet • Technology: Pebble system (sensor-controlled auger) • Advantages: Low water and energy consumption; versatile from breakfast service to happy hour • Applications: Smoothies, cocktails, food presentations, catering

Ice Flakes

Flaked Ice • Shape: Irregular thin flakes • Technology: Granular system (auger + ice crusher) • Advantages: Decorative and adaptive; ideal for displays and presentations • Applications: Fish counters, wellness centres, medical facilities, self-service

Ice Scales

Super-Chilled Flakes • Shape: Thin flakes (1.5–2 mm) at −5 °C • Technology: Fixed vertical evaporator • Advantages: Extremely cold, slow-melting ice; suitable for saltwater use • Applications: Fishing, meat and dairy industries, pharmaceutical applications

Corresponding Brema Series for Each Ice Type

| Ice Format | Ice Maker series |

| B-Qube | CB (Self-contained) |

| Ice Cube (Multi cube) | CB (Self-contained) / C (modilar) |

| Ice Finger | IMF (Self-contained) |

| Fast Ice | VM (Modular), VB (Self-contained) |

| Ice Pebbles | TB (Self-contained) |

| Ice Flakes | GB (Self-contained) / G (Modular) |

| Ice Scales | MUSTER (Modular) |

- The CB series is most popular for premium drinks – B-Qube cubes are ideal for cocktails.

- The IMF series produces Ice Finger – hollow cubes, preferred in bars and discos.

- The TB series with Pebble ice is versatile – from smoothies to presentations.

- The VB - presented by one self contained model with production of Fast Ice - bars, clubs, fast foods.

- The GB and G series are for flake ice – ideal for display cases, fish stands and wellness.

- The MUSTER series is for industrial applications – ice with very low temperature and high density.

Having introduced you to the different ice formats that Brema ice generators offer, we will now focus mainly on the most popular autonomous models with their own ice tank.

These models are self-contained – i.e. they have a built-in tank, which makes them ideal for bars, restaurants, hotels and medical applications.

Series with their own ice tank (self-contained)

| Series | System | Ice format | Hopper | Best for: |

| CB | Spray | Ice cube (Multi cube) | Yes | Bars, hotels, cafes |

| CB | Spray | Ice (B-Qube) | Yes | Cocktails, drinks, presentations |

| IMF | Paddle | Hollow cube (Ice Finger) | Yes | Disco clubs, bars |

| GB | Paddle | Granular ice (Ice Flakes) | Yes | Fish stands, display cases |

| TB | Paddle | Nugget ice (Ice Pebbles) | Yes | Smoothies, cocktails |

| VB | Vertical evaporator | Flat cube (Fast Ice) | Yes | Rapid cooling, beverages |

Let’s explore the technologies behind the perfect ice cube

Brema Ice Makers always keeps pace with the times, integrating the latest innovations in ice production.

Technologies in Brema ice machines

-

Spray system: Nozzles spray purified water onto a horizontal evaporator. Only the water in direct contact with the surface freezes, creating crystal-clear cubes (B-Qube, Ice Cube).

-

Paddle system: Rotating paddles shape ice around stainless-steel rods, producing hollow cylinders (Ice Finger) or pellets (Pebbles, Nugget).

-

Vertical evaporator: Ice builds up around a vertical cylinder. Ideal for fast cubes (Fast Ice) or thin, flat cubes (VM series).

-

Fixed vertical evaporator: Produces super-chilled flakes (Ice Scales) that fall directly off the evaporator at −5 °C.

-

Granular system: An auger and crusher generate flaked ice (GB/G series).

-

Pebble system: Sensor-controlled auger technology for micro-cubes (TB series).

-

PAM treatment: Special evaporator coating allows cubes to release easily (Fast Ice).

Models with built-in Drain Pump

Certain self-contained Brema machines offer a Drain Pump option, which provides:

-

Pumped drainage up to 1.5 m vertically and 15 m line length

-

No need for a floor drain or external siphon

-

Maintains compact footprint and machine hygiene

Air-cooled vs. Water-cooled

-

Air-cooled: Uses an internal fan to draw in and exhaust ambient air. Installation is simpler and no water supply is needed, but it requires good airflow, ambient temperatures below 24 °C, and regular cleaning of condenser coils from dust and grease.

-

Water-cooled: Transfers heat to an external water loop, ensuring stable production even at higher room temperatures or in confined spaces. Requires plumbing and drainage lines and consumes more water per kilogram of ice; with a recirculating system, energy use can drop by around 10% and condenser maintenance is reduced.

Eco-friendly refrigerant (R290)

All Brema models use natural propane (R290), which has an extremely low global-warming potential and excellent energy efficiency. R290 ensures reliable ice production at high ambient temperatures, meets the strictest European eco-standards, and can cut energy consumption by up to 10% versus traditional synthetic refrigerants.

Water-treatment options

-

Built-in antiscale filter (CB series): A cleanable cartridge module installs on the water inlet and can be serviced tool-free to protect the evaporator from limescale.

-

External filters: Polyphosphate and water-softening cartridge modules mount upstream of the machine to provide fine-filtration and reduce calcium and magnesium buildup.

Certifications (You can find all Brema documentations here)

Brema Ice Makers holds a full suite of international certifications for quality, safety, and sustainability:

-

UNI EN ISO 9001:2015 & UNI EN ISO 45001:2018 (quality & safety management)

-

First MOCA product certification (ICIM, 2017) under EU Reg. 1935/2004 for food-contact materials

-

CE marking & TÜV Rheinland validation for EU directives

-

NSF, cULus Listed, ETL Listed & ETL Sanitation approvals

-

Energy-efficiency certification by DOE & NRCan

-

Market approvals: EAC, KC, UKR, S-Mark, RCM & WaterMark

Automatic Washing System (AWS) – intelligent hygiene care

- All models in the Brema CB series (except 1565 and 1265) are equipped with the Automatic Washing System (AWS) – an automatic internal cleaning system that facilitates maintenance and guarantees higher ice hygiene.

- With a single push of a button located on the front panel, the machine performs a washing cycle that removes limescale deposits and residues, without the need for manual disassembly. (Brema Ice Machine Cleaner. This is a single-dose sachet, bio-based descaling agent.)

- This is particularly useful for bars, restaurants and high-consumption establishments where cleanliness is key.

- AWS not only saves time, but also extends the life of the machine by reducing the risk of contamination and technical problems related to limescale deposits.

Why Choose Brema?

- Reliability and durability: Stainless-steel AISI 304 body and high-quality components for years of trouble-free operation.

- High energy efficiency: Optimized refrigeration circuits help reduce electricity costs.

- Wide model range: From compact undercounter self-contained units to industrial series producing 20–5 000 kg/24 h.

- Excellent ice quality: Crystal cubes, hollow rods, pellets and flakes—seven ice formats for every application.

- Certified materials and safety: NSF, CE and FDA certifications ensure compliance with hygiene and food-safety standards.

- Professional service and spare parts: As Brema’s distributor for Bulgaria, we stock spare parts locally and offer certified service technicians.

How to Choose the Right Model?

- Calculate your required capacity (kg/24 h or kg/h) based on peak demand.

- Select the ice shape that suits your menu (cube, flake, micro-cube).

- Compare energy and water consumption (kWh/kg, l/kg).

- Decide if you need a self-contained unit with a storage bin and/or a drain pump.

- Consider dimensions, noise level and cooling requirements.

Why Tirol.bg Is Your Most Trusted Partner?

- Official Brema distributor for Bulgaria

- Local warehouse stock and fast delivery

- Professional installation and staff training

- Warranty and post-warranty service nationwide

- Door-to-door consultations tailored to your business

Frequently Asked Questions (FAQ)

- How do I determine the right ice machine capacity for my business? Estimate your average number of guests during peak times and multiply by 2–3 kg of ice per person per day. This gives you the approximate capacity (kg/24 h).

- Which ice shape is best for cocktails versus soft drinks and smoothies? B-Qube is ideal for premium cocktails; Ice Cube works for all kinds of beverages; Ice Finger and Pebbles excel at rapidly chilling soft drinks and smoothies.

- When should I choose air-cooled versus water-cooled? Air-cooled units are easy to install if you have good ventilation and ambient temperatures under 24 °C. Water-cooled machines maintain stable performance in warmer or confined spaces but require plumbing and drainage lines.

- What is a Drain Pump and when do I need one? A built-in pump that discharges condensate up to 1.5 m vertically. It’s useful where no floor drain exists or when you need to place the machine anywhere without extra drainage.

- How often should I clean the machine? Rinse the bin and internal surfaces daily. On models with AWS, run the monthly self-cleaning cycle. Arrange a preventive service check by a technician once a year.

- What are the typical energy and water costs? Expect around 0.3–0.5 kWh per kg of ice and 1.5–2.2 L of water per kg. Actual figures vary by model and ice format.

- Why does Brema use the eco-friendly refrigerant R290? Propane (R290) has a very low global-warming potential, high energy efficiency and meets Europe’s strictest environmental standards.

- What certifications do Brema ice machines hold? All models carry CE, NSF and FDA markings. The manufacturing process is certified to UNI EN ISO 9001 and UNI EN ISO 45001.

- What warranty and service does Tirol.bg offer? We provide a standard 24-month warranty with an option to extend up to 5 years, fast installation, staff training and full service support across Bulgaria.

Ready for professional-grade ice that makes a difference? Contact the Tirol.bg experts for a free consultation and demo of your first Brema ice machine!